The motor on my bandsaw is an old “Century” brand 1/2 hp single phase capacitor start induction design. I imagine it is as old or older than the machine so I wanted to go through it and clean it up. When I purchased the bandsaw it ran so I knew the motor was good. Here’s a pic of what it looked like when I got it home.

Since I’m sure you’re curious about its specs, here’s a picture of the data plate. Also in the picture I’ve taken the plates off that allow you to rewire the motor for either 115V or 230V. Today that’d be 120V or 240V but they had different standards back then.

To get the motor apart you need to remove the four larger screws on the end bell seen in the first picture. They run the length of the motor and poke out of the back end bell as seen in the second picture. You can see the long screws in the background of the picture below. Once the screws were removed I went around the circumference of the end bells with a block of wood and a hammer to remove them. As seen in the picture below, this motor has been used under the band saw for a long time. It was packed full of saw dust. I’m surprised it still ran!

Once the end bells were off I removed the rotor. The centrifugal switch on the rotor shaft is what switches out the starting capacitor circuit once the motor has neared run speed. I lightly lubricated the switch and removed the rust for the surface with very fine sand paper.

After cleaning the rotor up I cleaned all the saw dust out of the stator with a brush, vacuum, and air compressor. A large amount of sawdust had been removed when I was finally done.

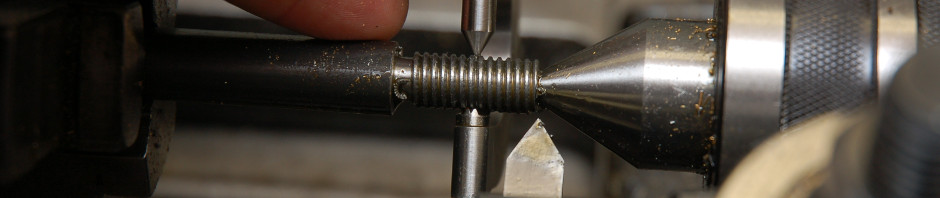

Instead of ball bearings like on most of todays motors, this one makes use of a brass bearing with wick oilers. If you look back to the third picture, the thing blocking the serial number is actually a rubber plug. There are plugs on both end bells. The plugs are removed and a electrical motor oil is poured into the cavity. In the cavities are wound pieces of twine that control the rate at which the rotor shaft is oiled. You can see the twine in the cutout of the brass bearing in the picture below.

Once everything was cleaned out the motor was reassembled. I cleaned the outside of the motor and gave it a wipe down with some oil. I also repainted the red dust cover since I thought it looked neat.

Here’s a short video of it running and slowing with no load. As you can see and hear it runs quietly and takes long time to wind down which I take to mean the bearings are good. You can also hear the centrifugal switch engage as it winds down. Unfortunately, under load there is a repetitive tapping when it running on the rear bearing. So, it’s not perfect but I think it’ll run for a long time under my light use.

Check out my other posts on the Craftsman Bandsaw: Disassembly and Finished

Do you have the measure meant for the pulley, I recently acquired this bandsaw but with no motor or pulley for the motor, so I need to find the size so I can match the rpm speed. Thanks!

Pingback: 10 Reasons: Why Is a Table Saw Smoking? [How to Fixed] – DrillAdvice.com